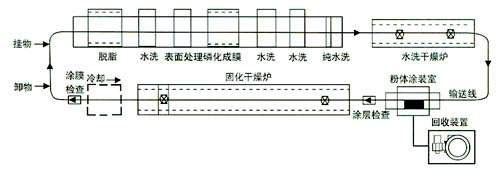

Pre- magani manual sauki tsari da kuma atomatik pre - magani tsari, karshen ya kasu kashi atomatik feshi da atomatik tsoma SPRAY biyu matakai.Dole ne a yi amfani da kayan aikin a saman don cire mai da tsatsa kafin fesa.A cikin wannan sashe an yi amfani da ruwa mai yawa, galibi mai cire tsatsa, wakili mai lalata, daidaitawar tebur, wakili na phosphating da sauransu.

A cikin sashin sarrafawa ko taron bita kafin layin samar da fenti, ya kamata a mai da hankali kan kafa sayan da ake buƙata, sufuri, adanawa da kuma amfani da tsarin acid mai ƙarfi da alkali, don ba wa ma'aikata suturar kariya da suka dace, riguna masu aminci da aminci; sarrafawa, daidaita kayan aiki, da kuma haɓaka matakan gaggawa na gaggawa da matakan ceto idan akwai haɗari.Abu na biyu, a bangaren pretreatment na layin samar da fenti, saboda samuwar iskar iskar gas, sharar ruwa da sauran abubuwa guda uku, don haka dangane da matakan kare muhalli, ya zama dole a daidaita fitar da iska, fitar da ruwa da sauransu. na'urorin maganin sharar gida guda uku.

A ingancin da pre-bi workpiece kamata ya zama daban-daban saboda daban-daban pretreatment bayani da shafi samar line tsari.Better aiki na workpiece, surface man, tsatsa yi, domin ya hana wani ɗan gajeren lokaci zuwa tsatsa sake, kullum ya kamata a cikin pretreatment bayan da dama matakai, phosphating ko passivation jiyya: kafin spraying foda, kuma ya kamata a yi phosphating workpiece. don bushewa, ga danshin saman sa.Ƙananan samar da tsari guda ɗaya, gabaɗaya ta amfani da bushewar iska ta yanayi, bushewar rana, bushewar iska.Kuma don yawan aikin kwararar ruwa, gabaɗaya ɗaukar bushewar ƙarancin zafin jiki, ta amfani da tanda ko bushewa hanya.

Spraying foda shafi kungiyar samar

Don ƙananan kayan aikin batch, na'urar da ake amfani da ƙura ta hannu gabaɗaya ana ɗaukar ta, kuma don babban aikin batch ɗin, na'urar turɓaya ta atomatik gabaɗaya ana amfani da ita.Ko manual ko atomatik kura, kula da ingancin yana da matukar muhimmanci.Don tabbatar da cewa spraying workpiece foda uniform, m kauri, don hana bakin ciki fesa, yayyo fesa, goge kashe da sauran lahani.

Rufi samar line a cikin tsari, amma kuma ya kamata kula da ƙugiya part na workpiece, kafin shigar da curing, ya kamata manne wa foda kamar yadda zai yiwu zai busa fita, hana wuce haddi foda curing na ƙugiya, wasu ga curing cire saura foda. kafin matsaloli, ya kamata a dace tsiri ƙugiya ya solidified foda fim, conductive don tabbatar da ƙugiya ne mai kyau, da kuma yawan kayayyakin gargajiya zuwa foda.

Production management na curing tsari a shafi line

Wannan tsari ya kamata kula da: fesa workpiece, idan yana da wani karamin tsari na guda samar, a cikin curing makera kafin kula da hana fadowa foda, kamar foda shafa sabon abu, ya zama dace fesa foda.Lokacin yin burodi, tsari mai tsauri da zafin jiki, sarrafa lokaci, kula da hana bambancin launi, akan yin burodi ko ɗan gajeren lokaci wanda ya haifar da rashin isasshen magani.

Domin manyan yawa na atomatik bayarwa na workpiece, a cikin bushewa hanya kafin kuma a hankali duba ko yayyo fesa, fesa bakin ciki ko na gida foda sabon abu, kamar samu unqualified sassa, ya kamata a rufe su hana shigar da bushewa hanya, har zuwa yiwu ga saukar da fesa.Idan mutum workpiece bai cancanta ba saboda bakin ciki feshi, za a iya sake fesa da kuma karfafa sake bayan warkewa.

Lokacin aikawa: Janairu-17-2022