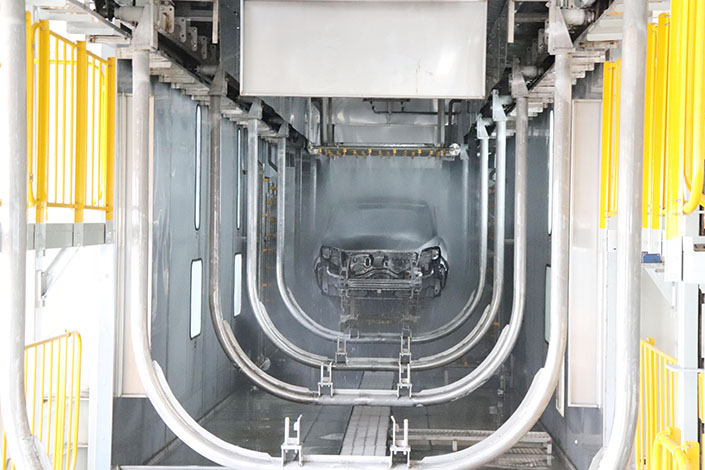

Fesa irin pretreatment samar line

Rufin pretreatment ya hada da degenreasing (degreasing), tsatsa cirewa, phosphating sassa uku.Phosphating shine hanyar haɗin gwiwa ta tsakiya, raguwa da tsatsawar tsatsa shine tsarin shirye-shiryen kafin phosphating, don haka a cikin aikin samarwa, ba kawai mu dauki aikin phosphating a matsayin mayar da hankali ba, amma kuma fara daga buƙatun ingancin phosphating, yi aiki mai kyau ban da ƙari. mai da cire tsatsa, musamman kula da tasirin juna a tsakaninsu.

Derusting

Tare da ci gaban masana'antu, kare muhalli da inganta yanayin aiki sun zama abin damuwa na kowa da kowa.Don haka, ya kamata a yi la'akari da buƙatar kare muhalli lokacin zabar wakilai.Sabili da haka, zaɓin wakili mai cire man fetur yana buƙatar shirye-shirye mai sauƙi, ikon ƙaddamarwa yana da ƙarfi, ba ya ƙunshi sodium hydroxide, silicate, OP emulsifier da sauran abubuwan da ke da wuyar tsaftacewa a dakin da zafin jiki, sauƙin wankewa a dakin da zafin jiki, ba ya ƙunshi mai guba. abubuwa, ba sa samar da iskar gas mai cutarwa, yanayin aiki mai kyau.Zaɓin mai cire tsatsa yana buƙatar haɗawa da masu haɓakawa, masu hana lalata da masu hanawa, na iya haɓaka saurin cire tsatsa, hana aikin aiki daga lalata da haɓakar hydrogen, zai iya hana hazo acid mafi kyau.Shin musamman cancanci acid hazo inhibiting, abin da ke faruwa a kan aiwatar da pickling acid hazo, lalata kayan aiki da kuma shuka, ba wai kawai gurbata yanayi, kuma zai iya sa hakori rube, hakori conjunctival ja, hawaye, zafi, bushe makogwaro, tari da sauran bayyanar cututtuka. , don haka yadda ya kamata ya hana hazo acid, ba kawai buƙatar kare muhalli ba, ko don kare lafiyar ma'aikaci.

Wankan ruwa

Wanke bayan cire man fetur da cire tsatsa, kodayake yana cikin tsarin taimako kafin zanen, yana buƙatar haifar da isasshen hankali.Bayan man kau da tsatsa kau, da surface na workpiece ne mai sauki bi da wasu wadanda ba ionic surfactants da CL-.Idan waɗannan ragowar abubuwan ba a tsaftace su sosai ba, za su iya haifar da ɓarkewar fim ɗin phosphating, lahani na layi, har ma da phosphating.Saboda haka, don inganta ingancin wanke ruwa bayan cire man fetur da kuma cire tsatsa, dole ne a bi ta hanyar ruwa mai yawa, rinses biyu, lokaci 1-2min, kuma akai-akai maye gurbin ruwa don tabbatar da cewa darajar PH na ruwa tsakanin 5-7 .

Phosphating

A abin da ake kira phosphating, yana nufin karfe workpiece bayan dauke da dihydrogen phosphate acid bayani magani, sinadaran dauki da kuma a cikin ta surface don samar da wani Layer na barga insoluble phosphate fim, da fim da ake kira phosphating fim.Babban maƙasudin fim ɗin phosphating shine haɓaka mannewa na sutura da haɓaka juriya na lalata.Akwai hanyoyi da yawa na phosphating, bisa ga zafin jiki na phosphating, za a iya raba zuwa high zafin jiki phosphating (90-98 ℃), matsakaici zazzabi phosphating (60-75 ℃), low zazzabi phosphating (35-55 ℃) da kuma al'ada zazzabi. phosphating.

Abin sha'awa

Ana amfani da fasahar wucewa ta fim ɗin phosphating a Arewacin Amurka da ƙasashen Turai.Fasahar wucewa ta dogara ne akan halayen fim ɗin phosphating kanta.Fim ɗin phosphating yana da bakin ciki, gabaɗaya a cikin 1-4G / m2, matsakaicin bai wuce 10g / m2 ba, yanki mai fa'ida kyauta yana da girma, kuma juriya na lalata fim ɗin kanta yana iyakance.Wasu ko da a cikin bushewa tsari a kan m rawaya tsatsa, bayan phosphating wani passivation rufaffiyar jiyya, na iya zama phosphating fim pore fallasa karfe hadawan abu da iskar shaka, ko samuwar passivation Layer, phosphating fim iya taka wani cika, hadawan abu da iskar shaka, sa phosphating fim barga a cikin phosphating. yanayi.

Bushewar fim ɗin phosphating

Bushewar fim ɗin phosphating na iya taka rawa guda biyu, a gefe guda, shine don shirya tsari na gaba don cire ruwa a saman fim ɗin phosphating, a gefe guda, shine don ƙara haɓaka juriya na fim ɗin. bayan shafa.

Don kafa layi na pretreatment shafi, dole ne a kammala tsarin ƙirar kafin ƙira, ƙira da shigarwa na kayan aiki marasa daidaituwa.Sabili da haka, ƙirar tsari shine tushe na layin samarwa, kuma madaidaiciyar hanya mai ma'ana za ta sami tasiri mai kyau akan aikin samarwa da ingancin samfur.

An yi amfani da shi don kowane nau'in zanen kayan aiki, sauran samfuran za a iya keɓance su.